EN 17092: 2020 Parts 1-6

Protective clothing for motorcycle riders

Dimensional stability

If the manufacturer’s instructions indicate that a garment can be washed or dry cleaned, the test procedure for dimensional change for washing of protective clothing material is to be carried out in accordance with EN 13688. Measurement of dimensional change is conducted according to ISO 5077. Changes in dimension due to cleaning of must not exceed ±5 per cent.

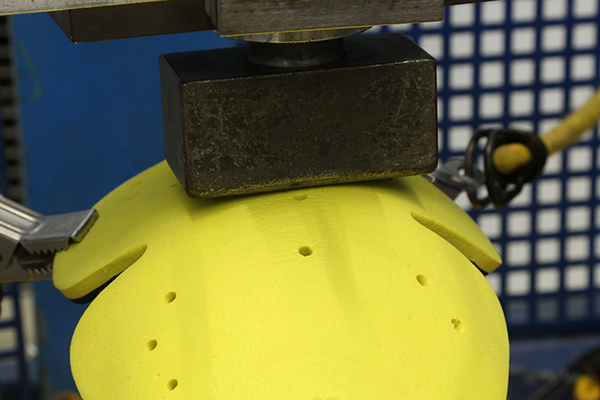

Impact energy absorption

Elbow, shoulder, knee and hip impact protectors are to be present in Class AAA and AA garments as a mandatory requirement, with the hip protectors being optional in Class A garments. EN 1621 impact protectors must be positioned in the garment so that they cover the appropriate body part, according to the relevant impact protector standard.

Class B garments are designed to provide the equivalent abrasion protection of Class A garments but without the inclusion of impact protectors. Class C garments are designed to provide impact protection for areas covered by the impact protector(s) only, and they do not offer minimum abrasion protection. Class C garments are intended to be worn with and supplement the protection offered by Class AAA, AA, A or B garments.

Impact abrasion resistance

This test simulates the stress that is placed on the protective garments when worn by an average rider (with a body mass of 75kg and a height of 1.75m), when sliding from variable initial speeds to standstill on a real concrete road surface.

All removable liners (for example, waterproof or thermal) are removed from the garment and the weakest combination(s) are tested. In one run, three specimens of the material(s) are mounted in holders in warp, weft and at 45 degrees. They are then attached to rotating arms positioned above a concrete tile. Once the desired speed has been reached, the specimens impact on the surface and come to a natural stop. If the specimens do not hole, the test is repeated a further two times. To pass, no holes with an opening of 5mm or more in any direction are to be present on the layer closest to the body.

Seam strength and structural closures

Each different seam type, zip fastener and protector pocket seam must be assessed for seam strength in accordance with the applicable zones as detailed in EN 17092-1:2020. Seams and structural closures are tested in accordance with EN 13594:2015.

Tear strength

Two-piece suit and garment sleeve restraint

Two-piece suits are engaged and a force of 100N is applied for 60 seconds. A visual assessment is carried out to ensure that no gapping or connection failures have occurred.

Cones are used to exert a circumferential force to the mandatory sleeve restraint systems. A force of 50N is applied to the cone for 30 seconds when all restraint systems are correctly adjusted. The cone must remain satisfactorily within the sleeve.