Building a bespoke laboratory

(SATRA LabPlus)

Among the many services offered by SATRA, its laboratory accreditation programme is one of the most popular. Over the last 15 years or so, hundreds of organisations have benefited from SATRA’s help and advice to set up their own in-house laboratory facilities, or gained SATRA accreditation for an existing laboratory.

SATRA has assisted such companies to establish either ‘B-grade’ production-quality laboratories or ‘A-grade’ laboratories, in which a range of test methods can be conducted accurately using specifically controlled environments to undertake testing. Manufacturers around the world have been able to use their facilities to differentiate themselves from competitors and demonstrate a commitment to producing a ‘quality product’.

SATRA’s expertise covers all types of footwear and shoemaking techniques, as well as the materials and components used in the manufacture of the finished products. This provides a unique advantage when it comes to advising on what tests are most suitable for manufacturers to carry out themselves. We are as experienced in discussing laboratory testing requirements with a safety toe cap manufacturer as we are with a producer of safety footwear, and as valuable to a fashion shoemaker as to a component supplier making insole boards or heels.

Being able to assess the performance of footwear and components is highly desirable for a number of reasons. Using appropriate test techniques, the quality of incoming materials can be verified, critical processes during manufacture can be controlled and validated, and the performance of the finished product can be predicted. Although many independent laboratories offer testing services, there is often greater convenience in having in-house test facilities, as they can give faster and cheaper results. An important consideration for many companies is that an in-house laboratory often forms part of their marketing strategy – demonstrating a serious management commitment to providing ‘quality’ products.

SATRA has identified the establishment of properly controlled and accredited laboratories as a major benefit to manufacturers, which complement our own comprehensive testing facilities. There will always be a need for independent third-party testing, and many retailers and brands will still require a SATRA test report. However, by developing a greater knowledge and understanding of their products’ characteristics, manufacturers are often not only able to bring improved quality products to market earlier, but also work more closely with both their customers and SATRA, to develop even better products or move into other footwear market sectors.

Questions to ask

At SATRA, we are often asked to advise on what is needed to set up both a quality control B-grade laboratory, or a more sophisticated and tightly controlled A-grade facility. The answer depends on a number of factors. Before commissioning a laboratory, four important questions need to be asked:

- What am I trying to achieve?

- What does my customer require?

- What materials or products do I need to test?

- What is my budget?

The answers depend on whether the laboratory is for factory production control, or more in-depth analysis of products and materials. The type of footwear or components being produced, and the materials from which they are made, will also be a factor. For instance, testing requirements for women’s high-heeled footwear made with leather uppers will differ from those for sports footwear made predominantly from synthetics. However, regardless of footwear type, some tests are universal. In addition to finished product testing, tests may be required on a variety of materials, including textile uppers, leather uppers and soling materials, as well as components such as toe caps, sewing threads, laces and eyelets.

There may also be a need to carry out chemical testing for levels of undesirable materials or restricted substances, such as restricted phthalates and azo-dyes, chromium VI, pH and organotin compounds.

The second question – ‘What does my customer require?’ – is, perhaps, the most important. While there are many definitions given for ‘quality’, the most important thing to remember is that quality is all about meeting customers’ expectations. Keeping customers satisfied is essential. Their requirements will play a large part in the kind of tests they would expect to be carried out and, consequently, the equipment needed. Many clients will want tests carried out to SATRA standards or relevant international, European or US standards. In some cases, brands and retailers may have their own test specifications that must be followed.

The last question is also critical. Whatever level of testing is carried out in the factory, it should be cost-effective while still satisfying customer requirements. A decision needs to be made – to set up a SATRA B-grade specification laboratory for basic quality control testing, or invest in a climatically controlled environment to satisfy the requirements of a SATRA A-grade laboratory. This decision will be influenced by the objectives for the laboratory. For example, if the laboratory is intended to demonstrate that test samples taken from bulk production are representative of products that have already been through a thorough initial-type evaluation, and the parameters being assessed are not unduly influenced by climatic conditions, a SATRA B-grade laboratory may be the most appropriate choice. Even for B-grade laboratories, some form of climatic control will usually be necessary, but the tolerance for this is not as fine as for an A-grade facility.

Selecting the equipment

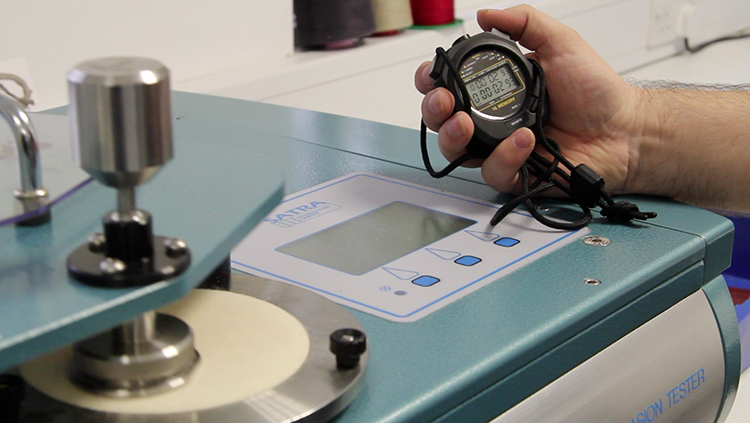

Deciding what test equipment is needed is actually a relatively simple step once the test methods being used have been confirmed. The first process is to obtain original and up-to-date copies of the test methods, which will identify the specifications of the equipment required.

Test equipment can be purchased from a number of manufacturers. However, it is essential that the equipment conforms to the requirements of the particular test method that you will use. If possible, visit other users of the equipment you intend to purchase and form your own opinion as to its reliability and appearance after continued use. Going for the cheapest supplier is often a false economy.

SATRA manufacturers a comprehensive range of test equipment for the footwear and leathergoods industries. Some of it is unique to SATRA and unavailable anywhere else. SATRA equipment also has the added advantage of having been used in our own laboratories and refined through user feedback before being sold commercially.

When making the purchase decision, ensure that you will also be provided with documentary evidence that the equipment has been calibrated against the requirements of the test method. Also make sure that the calibration certificates demonstrate traceability back to ‘national standards’ (that is, the calibration tools and instruments used to calibrate your equipment are themselves calibrated via reputable means back to a ‘master standard’ usually held by a country national standards body).

All SATRA equipment is supplied with documentary evidence of calibration and owner’s manuals detailing their use and routine maintenance requirements. SATRA also offers an on-site calibration and service package.

Training members of staff

SATRA’s experts regularly travel to member companies to provide training in testing. The only requirement for this service is that the necessary test equipment is available on-site. Where this is not the case, we can deliver training at SATRA’s headquarters in the UK, or at our facilities in Dongguan, China (subject to equipment availability).

We can provide interpreters if required, and trainees are expected to carry out tests under supervision rather than just watch someone else do so. SATRA also provides assessment services to finalise the training and to ensure it has been effective. Our training extends to interpretation of test results and, in many cases, guidance on identifying corrective action to improve poor performance.

Laboratory quality assurance

SATRA-accredited laboratories require a number of formal quality assurance-based control systems, which can be discussed with SATRA.

Laboratory accreditation is a service that is exclusive to SATRA members. Click here to find out more about the benefits of SATRA membership.

Improved customer confidence

SATRA strongly believes that development of a SATRA Accredited Laboratory brings significant benefits to companies – whether materials, components or finished product suppliers – both in terms of product development and a demonstrable commitment to quality.