Work clothing for protection against stabs and cuts

A number of occupations involve the use of hand-held knives, bringing with them a risk of accidental injury.

Workers who habitually use hand-knives in industrial environments, such as abattoirs and meat processing plants, are particularly vulnerable to accidents and injuries involving stabs and cuts. Therefore they should be provided with adequate protective equipment.

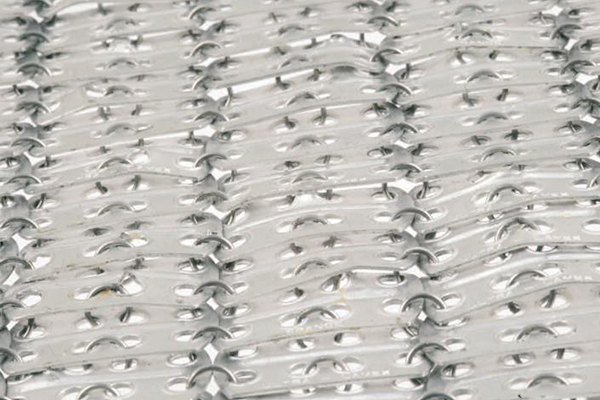

The performance of clothing designed to protect against cuts and stabs from hand-knives is specified in Europe by EN ISO 13998:2003. This standard, which supercedes EN 412:1993, covers the performance and classification of a range of garments including aprons, trousers and vests. Whereas EN 412 only covered metal plate (pictured above) or metal ring/chainmail aprons, EN ISO 13998 covers these and garments made of other materials, such as textiles. It provides two performance levels for clothing that offers protection against cuts and stabs.

The basic requirements for garments covered by EN ISO 13998 include innocuousness, sizing, dimensions of zones of protection, support and restraint, mass, ergonomics, penetration and/or cut resistance and the tensile strength of metal ring or plate materials. There is also an optional water resistance requirement. The innocuousness section requires aprons and garments to be free from features and chemicals or substances that may harm the wearer. For example, it is necessary for metal components (rings, plates or links) to meet the requirements for nickel release in REACH Regulation (EU) 1907/2006, Annex XVII entry 27.

The sections on sizing and minimum dimensions of the zones of protection require that aprons and garments are marked with the size of the wearer they are intended for and that they provide coverage and protection over specified areas.

The requirement for mass is simply to prevent excessively heavy garments, which may put undue strain on wearers, from being placed on the market.

The guidelines for the support and restraint system focus on ensuring that these components do not place undue pressure on wearers, but are strong enough to resist moving out of place when subjected to pulls. An ergonomic assessment procedure is also included to quantify any discomfort or impediments caused when wearing the garments.

The blade penetration requirements differ depending on whether the garment being tested is metal or textile. For both types of product, the initial penetration requirement calls for the use of a specific steel probe, the size of which depends on whether the product under test is performance level one or two. This probe is pushed against holes or gaps in the protective area to ensure that it cannot penetrate the garment.

Following this, an impact penetration test is carried out. This involves dropping a weighted knife blade onto the test sample and measuring the penetration of the tip of the knife blade though the sample. For level one products, the impact energy in this test is 2.45J, which is obtained from the 1kg mass of the knife-holding block falling through 0.25m. For level two products, the same knife-holding block is dropped through 0.5m resulting in an impact energy of 4.9J. The mean penetration measured from the underside of the material to the tip of the knife blade must not exceed 10mm for level one products and 12mm for level two products. In addition, no individual penetration must exceed 17mm for level one products and 15mm for level two products.

There is a further requirement for level one products not made from metal rings or metal plates. This is that they must achieve a cutting force of at least 50N when tested according to EN ISO 13997 (‘Protective clothing – Mechanical properties – Determination of resistance to cutting by sharp objects’). There is also a requirement for the minimum breaking strength of all metal products. This is 100N for level one and 200N for level two.

The optional water permeability requirement specifies that the textile material used in a garment is impermeable to liquid water under a pressure of 200 kilopascals (kPa).

Further information on SATRA’s PPE certification and testing services is available at www.satra.com/ppe

How can we help?

15 PER CENT DISCOUNT ON FIRST SATRA TEST – please click here.

In Europe, garments designed to protect workers that use hand-knives from cuts and stabs are covered by the PPE Regulation (EU) 2016/425. Before having the CE mark affixed to them and being placed on the market, such products must undergo a type examination by a Notified Body such as SATRA. For more information, please email [email protected]