SATRA TimeLine: Typical Workflow

The SATRA TimeLine workflow is a simple, easy-to-use process designed to provide rapid, accurate and achievable time standards for all shoemaking operations. Comprehensive training is given for all of the elements covered below.

1: Method Analysis

The process starts with an understanding of the typical operations to be carried out by the company. In order for SATRA TimeLine to deliver accurate times, it is important to start with a correct analysis of the working methods and equipment for any operations required for the work.

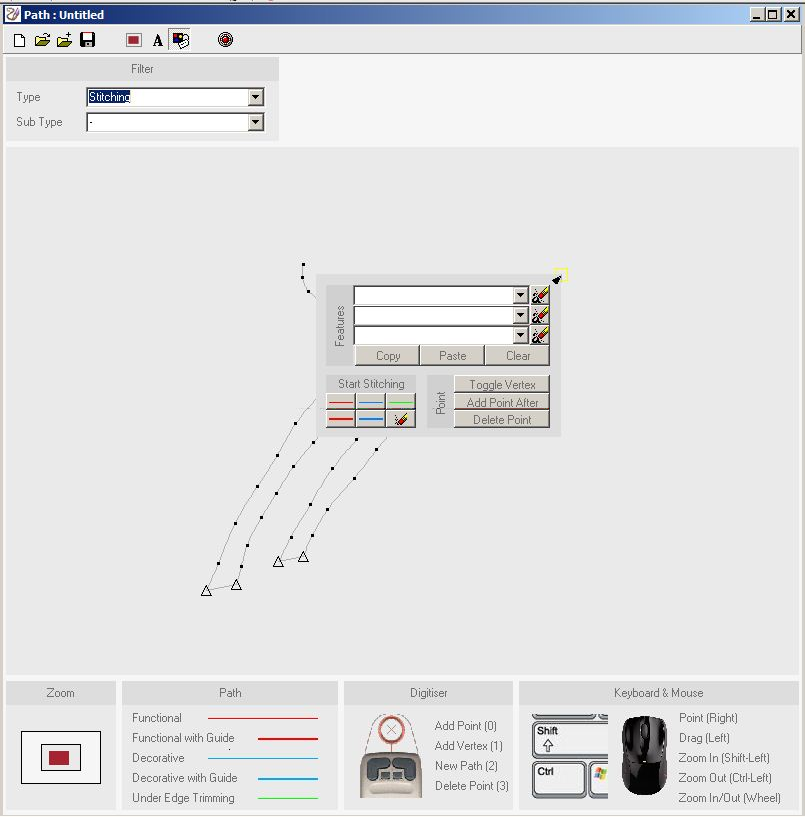

2: Creating Paths

SATRA TimeLine uses a digitiser to enter any paths needed for operations such as stitching, skiving, cementing and folding.

These paths will be supplemented with features (such as corners, back taks and seam obstructions) to enable the SATRA TimeLine software to analyse and calculate the appropriate operation time. This time will include any acceleration or deceleration needed to allow the operator to deal with the features.

Once digitised, a path can be used for any number of operations.

3: Creating elements

SATRA TimeLine comes with almost 400 preloaded elements; these can be modified or added to so as to reflect the exact working methods and conditions in the user’s factory or for a specific job.

The elements are created from motions, the most basic building blocks of the system – motions are based on low-level PMTS movements (such as reaching or putting) together with the distances needed.

Once fully trained, the system user will be able to use these motions to create tailored elements for their own specific use.

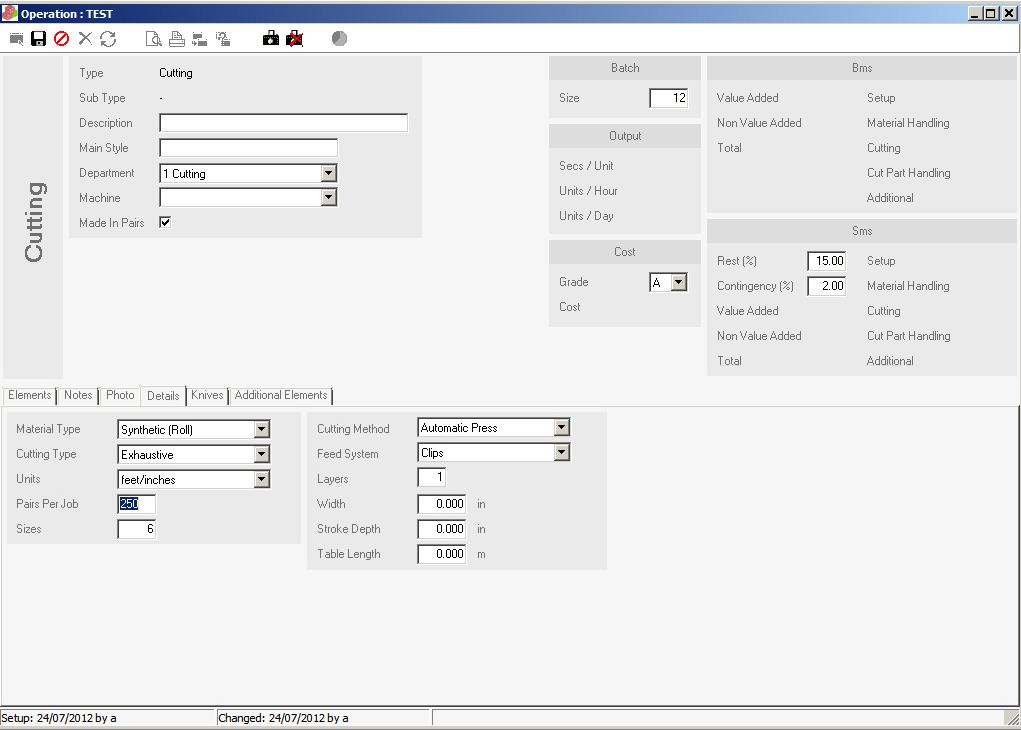

4: Calculating operating times

SATRA TimeLine operation values can be calculated for virtually any shoemaking task.

The process of calculating operation times requires the user to answer questions that cover work transportation, handling and the use of tools or equipment. The system uses the answers to these questions to automatically select elements and apply them with the appropriate frequency to build up the operation time.

The result shows a detailed method with times for each operation, which can be used as a training or performance monitoring tool, and it also identifies the balance between added and non-added value time. This allows the product engineer to consider any changes to the working method which could increase the efficiency of the operation.

5: Creating styles

Building up sub-styles and styles from the values enables SATRA TimeLine to estimate the total time required to manufacture the shoe. The operation set collects together all the operation values for a particular department, and the style describes the whole construction process from cutting the raw materials to boxing up the final product.

6: Costing and reporting

SATRA TimeLine allows you to assign rates for each operation using a range of different grades of work. SATRA TimeLine will then calculate how much each operation will cost before going into production to show both the manufacturing costs of the direct labour needed and also if the user has a payment incentive scheme.

Printed reports of all of the information are available which can then be used for the user’s internal administration and to show a commitment to continuous improvement. The same information can be exported electronically into other databases (for example, into whole shoe costing or bill of materials files).

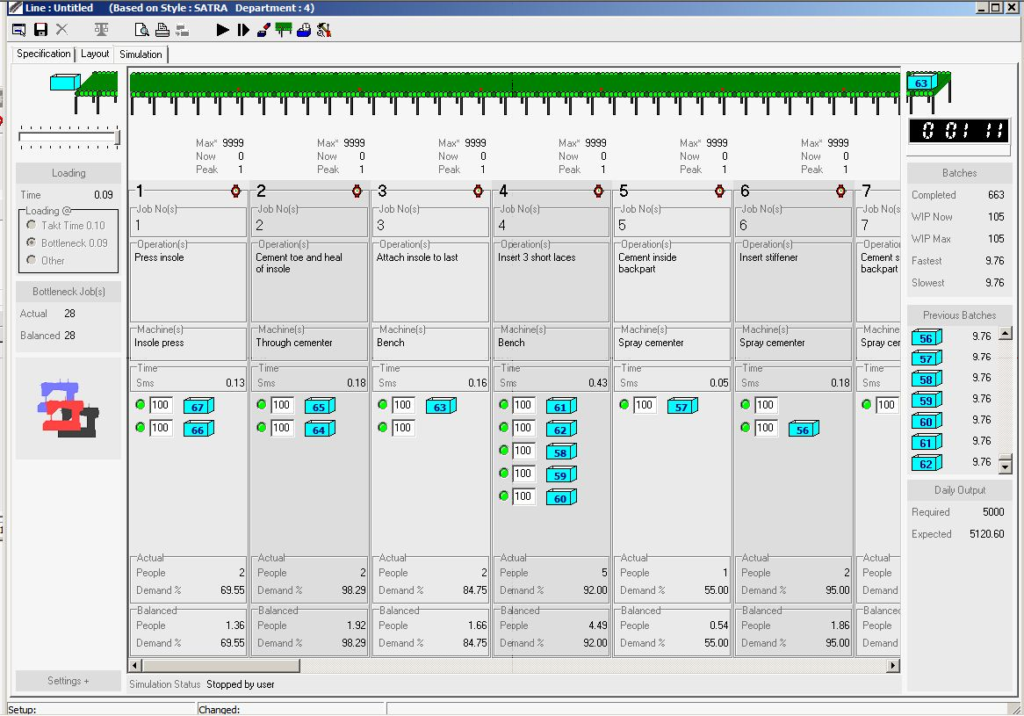

7: Line balancing

Once all the operations needed to make a style have been calculated, these can be used as the basis for predicting and monitoring actual production.

Within SATRA TimeLine there is a sophisticated module which allows the user to select a specific department, or group of operations, and contrast these with the production resources available. The software can show the expected output and optimal line balance, or indicate the resources and time needed to manufacture a specific quantity of a style.

Each operation will show the ratio of added and non-added value, allowing the product engineer to consider ways of reducing the wasted effort and improve the efficiency of the operation.

Once the balance is considered acceptable, SATRA TimeLine will show a visual simulation on your screen of the production over a selected period, displaying the flow of work along the line. Each work station will show itemised data such as the number of people required and their overall productivity. For operations that involve unmanned machines (such as heat-setters, chillers etc.), the time in the machine and feed rates are required. If these operations need to be limited (for example, by reducing the flow of work before the end of the working day) this can also be included and SATRA TimeLine will then show the actual output expected.